Our Business

- Home

- Our Business

- moving forward with the evolution of microwave and millimeter wave technologies

- Electronics and Communications Equipment

- supporting energy conservation and efficiency improvement in the manufacturing industry with high-frequency induction heating technology

- Industrial IH Equipment

From social infrastructure equipment such as wireless communications and radars, to components for installation on satellites and radiological equipment — Electronic/Communications Equipment by SPC Electronics continue to explore new applications in microwave and millimeter wave technologies. In addition to manufacturing products with high performance and high reliability, we are also focusing on developing products that meet new needs, such as 5G and IoT.

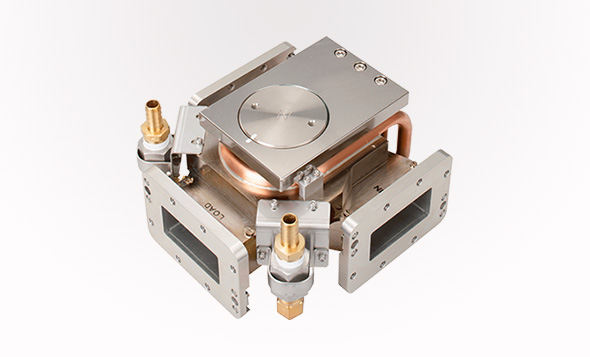

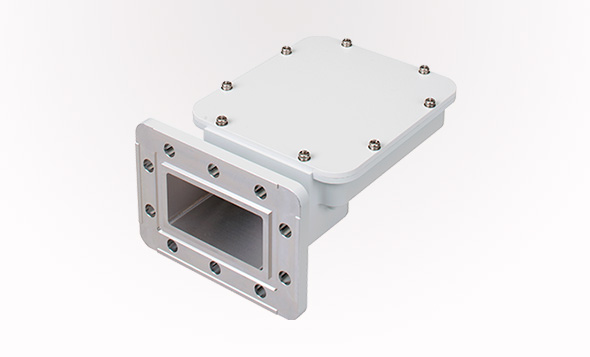

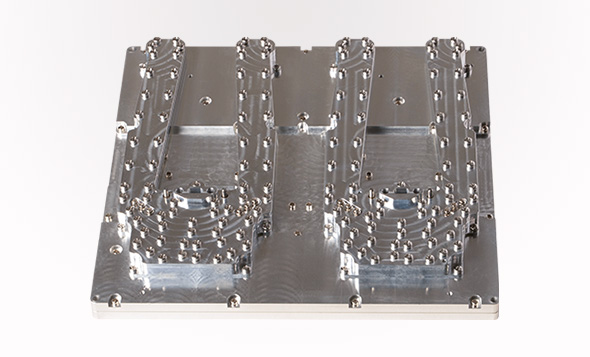

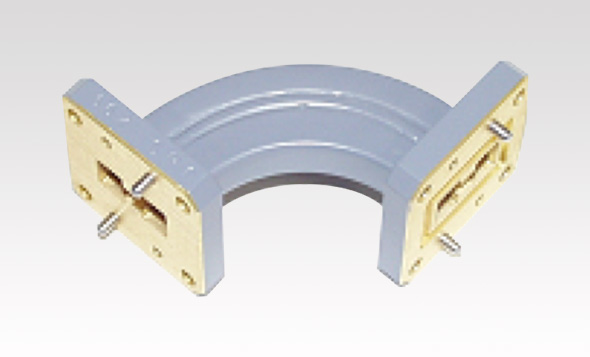

Components for Use On Satellites

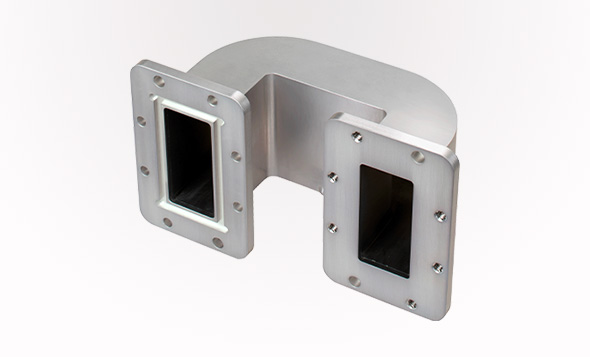

SPC Electronics’ components for use onboard satellites play an active role in communications, broadcasting, positioning and Earth observation. For instance, waveguides that transmit radio waves efficiently and circulators that control the direction of radio waves require not only efficient performance but also rigorous control to maintain light weight and reliability to operate stably in harsh environments. SPC Electronics makes use of its design technology cultivated over many years, and advanced manufacturing technology like dip brazing to meet the stringent requirements demanded by the aerospace industry.

Thin-walled Waveguide

Waveguide Component

Coaxial Component

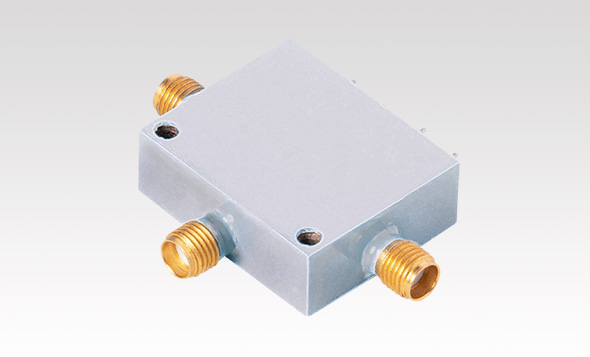

MIC Circulator/Isolator

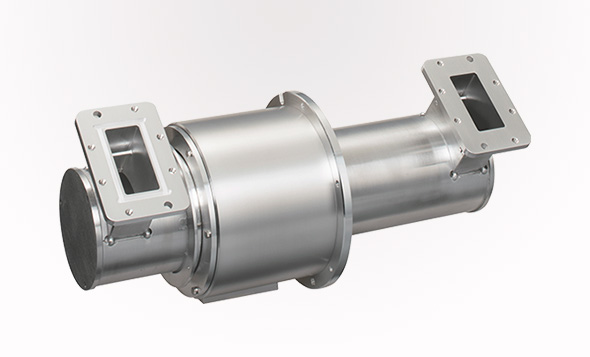

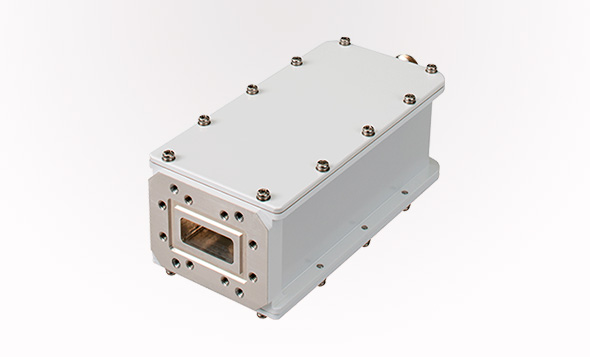

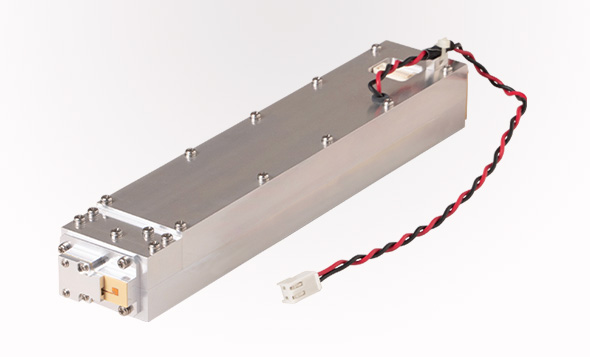

Components for Radiological Equipment

Radiological equipment, which play a vital role in the field of medicine, require components such as RF drivers for generating high microwave output, waveguides for transmitting radio waves and rotary joints. SPC Electronics provides components that meet the requirements of advanced medical treatment, through advanced designing technology for high output microwaves and reliable manufacturing. Our components are widely accepted by medical equipment system manufacturers both in Japan and around the world for their high evaluation of performance, strict delivery management and quality control.

Waveguides

Circulators

Rotary Joints

RF Drivers

LNBs for Satellite Communications

VSAT, or very-small-aperture terminal, is becoming popular worldwide as a low-cost communication network. At SPC Electronics, we provide a variety of LNBs (low noise block downconverters), which are the receiving components of VSAT. These components work for a number of frequency bands including S, C, X, ku, and ka bands, and are highly evaluated by global communications equipment manufacturers for their compactness and low noise. In the future, we will be further extending our lineup with products that support higher frequency ranges such as the Q and V bands, and meet new demands of high-speed, high-capacity transmission in satellite communications.

C-Band PLL LNB

X-Band PLL LNB

Ka-Band PLL LNB

Ka Dual LNB

Millimeter Wave Data Transmission Equipment

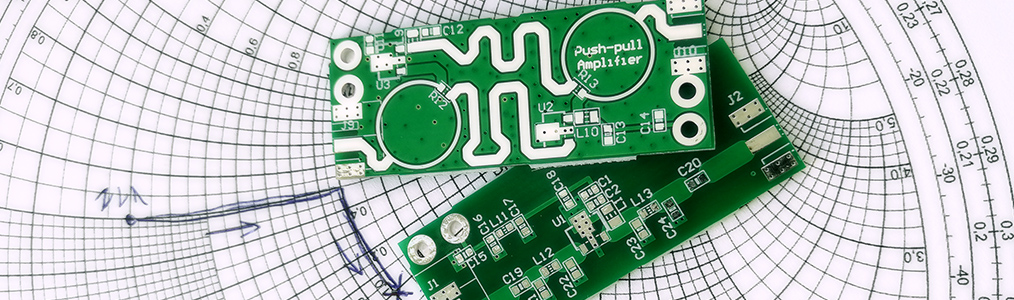

SPC Electronics has been developing a variety of millimeter wave modules suitable for high-speed transmission of high-capacity data, utilizing microwave circuity design technology and high-density mounting technology that we’ve cultivated over the years, for the proliferation of 5G networks. Diverse applications are anticipated including data linkage system between sites, a local 5G system that manages plant facilities and equipment over a wireless network, and communications with transportation vehicles such as trains. A new communications infrastructure that is resilient against disasters, yet offers excellent system scalability and mobility, will support society in the future.

Millimeter Wave Front-end Module

28GHz Frequency Conversion Unit

60GHz-range Frequency Converter

Introduction of Millimeter Wave Data Transmission Equipment Products

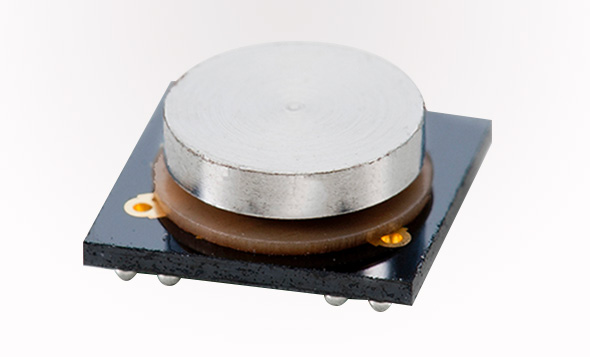

Radar Equipment

Public facilities and equipment to protect the safety and security such as monitoring radar for airport land surfaces, radar for ships to support their navigation, and weather radar to predict torrential rains are also supported by SPC Electronics' technology. We provide waveguides that connect antennas to transmitters, rotary joints, small circulators used in the latest array antennas, and simulators for radar testing.

Rotary Joints

Surface Mount MIC Circulator

Double-ridge Waveguide

RF Switch

Others (Microwave / Millimeter-Wave Components and Test Equipment)

Microwaves and millimeter-waves are used in a wide range of industries such as aerospace, communications, and radar. We provide a broad selection of components and test equipment to verify the functions and performance required for utilization in each field.

In addition to industrial fields, we also offer experimental equipment that allows students to systematically learn from basic experiments of microwave technology in order to develop human resources who will be responsible for the future of society. This equipment has been adopted for use by many university engineering departments, technical colleges, and industrial high schools. Over the years, we have manufactured and sold microwave and millimeter-wave equipment in a wide range of frequency bands, functions, and performance. SPC Electronics will continue to provide a broad selection of products and services that apply radio wave technology.

Micro-wave Testing Equipment

Digital RF Simulator

Wideband Coaxial Component

TACAN Simulator

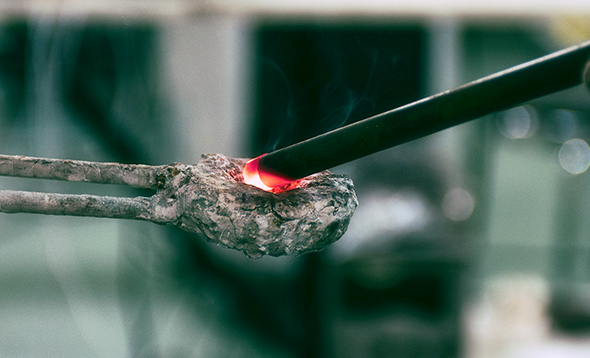

As a pioneer in the field of high-frequency induction heating, SPC steadfastly addresses the challenges of our customers in the manufacturing industry. Our 70 years of experience in this field have led to the development of industrial IH equipment optimized for the heat treatment of various metals. Our one-stop service includes sample testing, manufacturing and start-up support to ensure that we meet the needs of our customers.

Ever Evolving High-frequency Power Supply

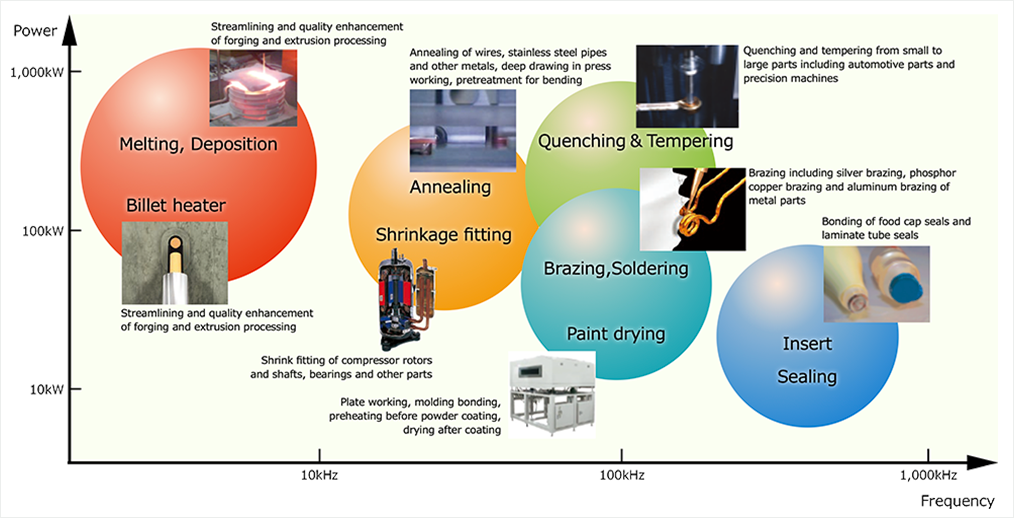

SPC Electronics offers a variety of high-frequency power supplies delivering 5 to 1,000 kilowatt output and 1 to 400 kHz frequency range to meet diverse applications. We have also introduced a new power supply — PWM-controlled High-power Induction Heating Inverter — capable of supporting high power output of over 1,000 kilowatts, achieving a 30% increase in efficiency compared to conventional models, into the market to address a broad array of needs at manufacturing sites.

Heat Treatment Application

Wide range of applications

The Induction Heating (IH) method, which uses an induction current to generate heat in the metal itself, is highly regarded by customers in various industrial fields as a method of heating that is faster, higher temperature, and more efficient than combustion or electric heating, as well as being energy efficient, productive, and environmentally friendly. From melting/deposition, quenching/tempering, shrinkage fitting, annealing, forging, brazing/soldering, to paint drying, paint coat removal, and sealing, we contribute to reduced cost as well as improved productivity and quality in all sorts of heat treatment.

Applicable Industry Fields

Automotive

- Heat treatment of high-tensile steel sheet

- Bonding and drying of plate parts

- Heat treatment of shafts, gears, and bearings for electrical components

- Adhesion and drying of insulating powder

Mechanical Parts

- Lightweight parts made from press quenched thin plates

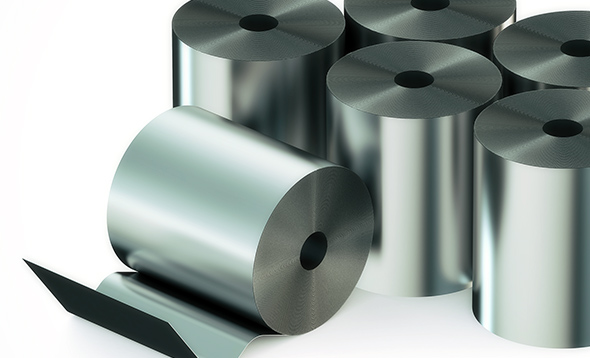

- Various hoop materials

- Heat treatment of thin sheets of construction materials

- Laminated welding

Consumer Electronics

- Preheating of the enclosure for household appliances (white goods)

- Shrinkage fitting of rotors and shafts for compressors

- Brazing of refrigerant pipes

Semiconductors

- Heat treatment of sputtered plate materials

- Heat treatment of thin plates such as lead frame materials

- Epitaxial growth system

- Melting of materials

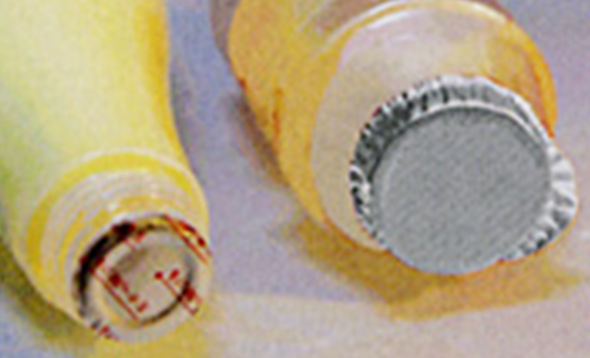

Chemicals/Pharmaceuticals

- Aluminum deposition for cosmetic containers

- Laminated tube welding

Food Products

- Welding of aluminum caps

- Laminated tube welding

- Lamination of Beverage Cans

One-Stop Service

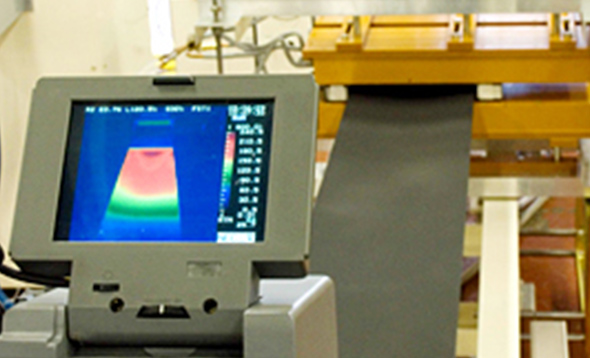

At SPC Electronics, we support our customers in solving their metal heat treatment issues by responding to the needs of their production sites. We use the latest computer simulators to design heating coils that are optimized for the workpiece being heated, and reflect the results of sample tests to offer proposals that lead to improved productivity.

One-Stop Service

Computer simulation

Sample testing

Power source setup, Heating coil design

Delivery/Operation

Maintenance

Wireless Power Supply

The use of electromagnetic induction technology, which is used in industrial IH, is attracting attention as a new energy supply method for the next generation. SPC Electronics commercialized an inverter for wireless power supply in 2008, and we also participated in demonstration tests of power supplies in running electric vehicles. We will be contributing to the development of contact power supply systems for next-generation infrastructure, including automobiles, railroads, and personal mobility.